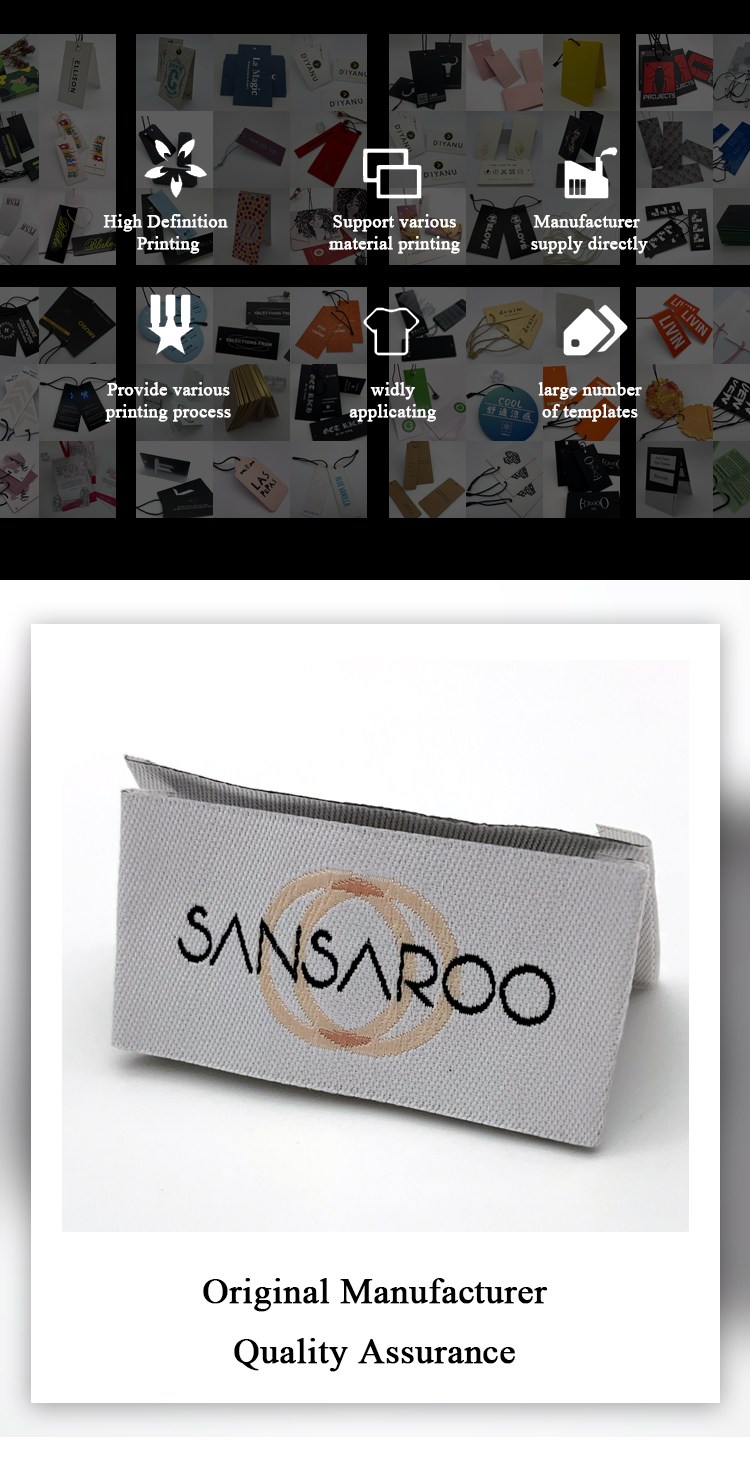

Luxury Fabric Tags Custom Jacquard Golden Logo Hot Cut Damask Woven Labels For Clothing

Material

The material of Woven label is polyester yarn,we can even produce woven label by metallic thread if you need.

Colors

We use Pantone colors to match the thread,Please note that 100% color matched is not guaranteed but we try our best to come as close as possible to the Pantone color provided.

1Labels can have up to 8 colours

Size:

The label can be customized to any size as you need.Our designer will draw mock-up for your approval before production.

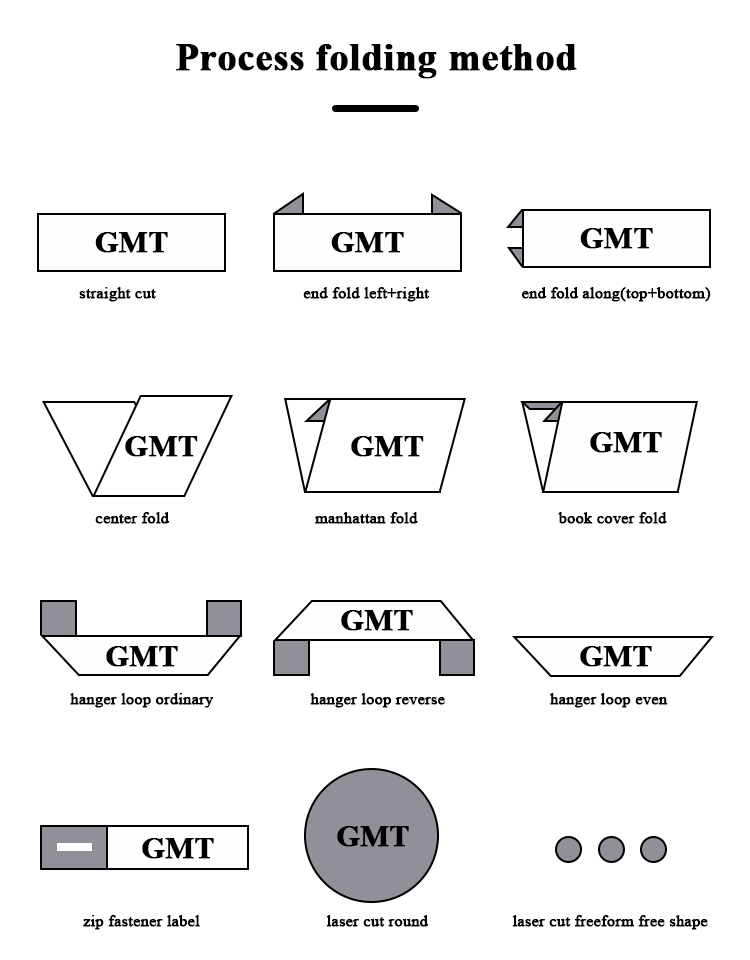

Packing & Folding ways

The label can be packed in roll or cut to unit as your requirement.

We can also help you to finish the folding process.Please choose one folding way before production.

Minimums order quantity:

500 pieces.

Turn around Time:

3 business days for samples. and 5-7 business days for production

Write your message here and send it to us

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

WeChat